This review will inform other design decisions so that the efficiency of the aircraft can be maximized. A rigorous review will identify and mitigate the sources of drag across the aircraft. The SNLF concept will be strengthened by enabling technologies, including active flow control to enhance maximum lift and piezocomposite trailing edges as a control effector. The airfoil will be tested in in the NASA Ames 11ft Transonic Wind Tunnel to demonstrate the viability of the SNLF technology. This will guide the design and optimization of the final SNLF airfoil. These results and predictions will be validated by a series of wind tunnel experiments. Technology development and integration will be driven by computational research to simulate the performance of the wing and components. Research tasks will proceed in three phases:Ĭarrying out research tasks at each of these phases will be a collaborative effort that brings together industry partners, faculty, and students across the country to achieve a series of research milestones. These innovations will be integrated into the design of a fixed-wing aircraft with the SNLF airfoil.

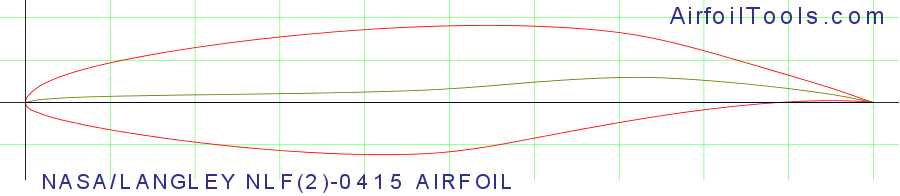

In parallel, research will explore opportunities to incorporate enabling technologies, such as advanced materials, new propulsion configurations, fluidic oscillators and adaptive trailing edges. Researchers will employ both computational and experimental methods to develop and refine the concept of the SNLF airfoil. Pairing the SNLF concept and TTBW configuration will minimize drag across the wing, paving the way for ultra-efficient flight! The airfoil will be integrated into a transonic truss-braced wing (TTBW) configuration. Through the N ASA-funded University Leadership Initiative, the University of Tennessee-led team will build on this progress by maturing the SNLF airfoil for use in a fixed-wing, commercial aircraft. This concept promises to streamline wing design: reducing weight, drag and the need for thrust – which all contribute to the objective of reducing fuel consumption. An aircraft utilizing an SNLF airfoil could achieve the lift necessary for landing at low speeds without the added weight of larger landing flaps or more surface area on its wings. The SNLF airfoil also has a much greater capacity for lift than its single element counterpart. By minimizing turbulent flow, the SNLF design will achieve more efficient flight at cruising speeds. Turbulent flow disrupts the parallel flow of air, creating resistance, or drag on the airplane. At higher speeds, airflow transitions to turbulent flow across certain shapes. This is called laminar flow and is characterized by the “orderly” flow of air in parallel layers. The mutual interaction of these two elements promotes more favorable airflow and pressure across the wing. How can an airplane harness airflow for more efficient flight? In contrast to conventional, single element airfoil designs, the SNLF design incorporates a slot which acts as a second element on an aircraft wing.

0 kommentar(er)

0 kommentar(er)